CNC machining is not a new word, the concept of the idea of many years ago was raised, with the development and progress of the times, this technology began to gradually improve the development of a wide range of industries in recent years when the product is widely used in manufacturing. Then today we will take you to understand the CNC machining technology and CNC machining centers.

What is CNC machining?

In the long history of development, people in pursuit of high quality, high yield, high efficiency and design of mechanical processing machine tools, promote the mechanization of industrial production. The so-called CNC machining is a technology that gives up the complicated human work and chooses to carry out production and processing activities through computerized numerical control (Computerized Numerical Control) machine tools. Therefore, it is also known as CNC.

Advantages of CNC machining

The biggest difference between CNC machining and traditional machining is that the former adds digital control to the latter. In addition to this, what are the advantages of CNC machining over traditional machining, which is known as the future trend of industrial development?

High efficiency

The greatest advantage of the computer is its powerful computing power and information processing speed. CNC machining inherits this characteristic perfectly. With the optimization of the digital control system, the performance of the core processor is also constantly improving. The efficiency of CNC machining is ten or even ten times higher than that of mechanical machining for the same product.

High Precision

With the continuous improvement of products, people have higher and higher requirements for the quality of processing. In the process of machining, because of high-speed vibration, high temperature caused by the processing of product error is also becoming more and more important. CNC machining can be precisely controlled by computers to compensate for errors and improve machining accuracy to ensure the quality of processed products.

Intelligent

Intelligent is the biggest feature of CNC machining, with the continuous development and upgrading of technology, CNC machining of the operating system is also constantly optimized to meet the development needs of industrial production and processing. At the same time, the requirements for operators are reduced so that they can quickly get started.

Open design

As a constantly evolving technical equipment, the software and hardware equipment are in line with international standards and can be replaced in line with the development of the times. In addition, the machine tool equipment can be adjusted according to the customer’s requirements to meet the specific conditions for processing special products.

After understanding the most basic concepts and advantages of CNC machining, we would like to introduce you to the most popular CNC machining centers on the market, which are the most frequently used in our lives.

CNC Machining Center

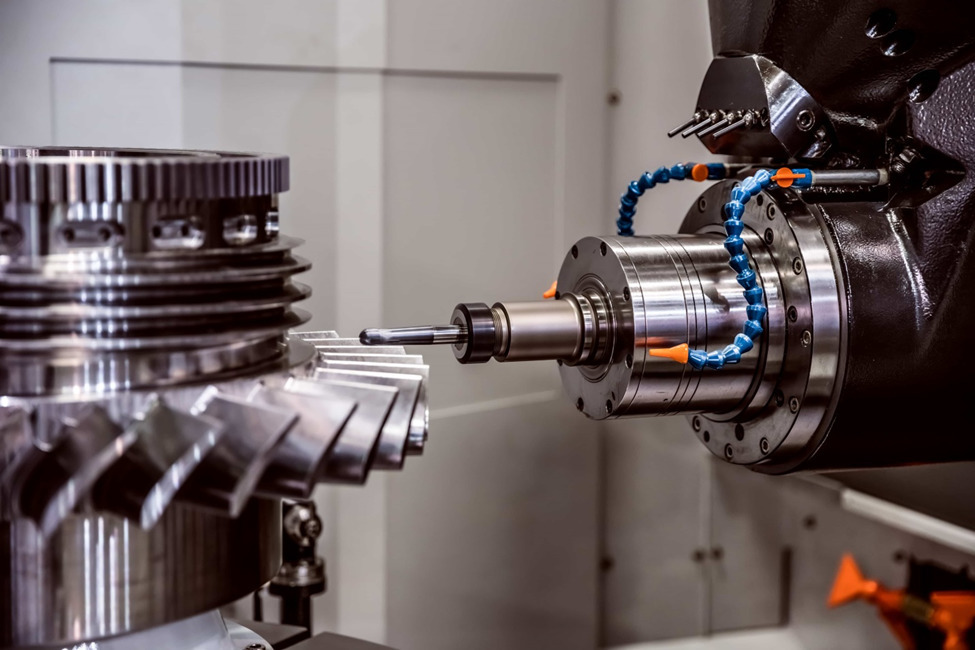

Although CNC machining centers are called “centers”, but it is not everyone thinks of CNC machining of a workplace, but a full-featured, with a variety of machining processes of a type of CNC machine tools. As the most popular CNC machine tool for industrial production, it also represents a type of development trend of CNC machining. Its main features are as follows:

Fully enclosed protection

CNC machining centers are in a fully enclosed state when they are in working condition. In this way, the safety of processing is greatly improved, greatly reducing the probability of injury to the workforce due to accidents.

Equipped with tool magazine, automatic change

CNC machining centers and ordinary CNC machining machine tools is the biggest difference in its equipped with a tool magazine, which is designed to allow CNC machining in a product processing according to the wisdom of the setup to replace the tool to complete multiple machining processes, without having to stop machining, manually replaced, thereby improving the efficiency of product processing.

Combined machining, powerful functions

CNC machining centers can be equipped with multiple tooling stations to perform multiple tasks simultaneously. In addition, the rich tooling equipment allows CNC centers to have functions such as milling, grinding, hole tapping, etc. Compared to other types of CNC machining machine tools that have a single function, they can realize more operations and have a wider range of processing and capabilities.

Work process concentration

CNC machining centers usually have a number of spindles and feed axes, in the CNC machining can be from multiple angles, directions, the use of multiple types of tools, multi-axis linkage, simultaneous machining, process-intensive, fast production efficiency, usually 5 to 10 times that of ordinary equipment.

Development Prospects

With the development of the times change, the repetitive mechanical production and processing work will certainly be replaced by intelligent production. And CNC processing work as the mainstream trend of future industrial production, the development prospects can not be said to be bad. Moreover, as a technical work type, it is helpful for people to have relevant experience and master sufficiently skillful techniques for future development.

Post time: Aug-26-2023